Introduction: Understanding Robotics

Robotics is transforming industries at an unprecedented pace. What exactly is robotics? Simply put, robotics involves the design, creation, and use of robots to perform tasks traditionally carried out by humans. This technology has evolved rapidly over the past few decades, bringing robots from science fiction into our everyday lives.

The History and Evolution of Robotics

The concept of robots dates back to ancient times, but it wasn’t until the mid-20th century that real-world robots began to make their debut in manufacturing. Fast forward to today, and robotics spans multiple industries including healthcare, agriculture, logistics, and even our homes. The evolution of robotics has paved the way for greater productivity, innovation, and efficiency.

Types of Robots in Modern Industry

Robots come in a wide variety of types, each serving a specific role in different sectors. Some of the most common types of robots include:

Industrial Robots

These robots are used primarily in manufacturing for tasks like assembly, welding, and painting. They are built to handle repetitive, high-precision tasks that require consistency and speed.

Service Robots

Service robots are designed to perform non-manufacturing tasks such as cleaning, delivery, and surveillance. These robots can operate autonomously and perform tasks like vacuuming or delivering products to customers.

Autonomous Mobile Robots (AMRs)

AMRs are capable of navigating environments independently. They’re widely used in warehouses, hospitals, and large facilities for tasks such as transporting goods, managing inventory, or delivering medical supplies.

Robotics in Manufacturing

One of the key sectors where robotics is making a huge impact is manufacturing. Robots are transforming assembly lines, improving efficiency, and reducing errors.

Automation and Efficiency

Robots can work tirelessly 24/7, producing consistent output without the need for breaks or sleep. This level of automation increases production speed and reduces the margin of error that often comes with human labor.

Collaborative Robots (Cobots)

Unlike traditional robots that operate in isolation, cobots are designed to work side by side with human workers. This collaborative approach allows robots to handle mundane or repetitive tasks, freeing up human workers for more complex and creative jobs.

Robotics in Assembly Lines

The integration of robotics into assembly lines has led to increased precision and decreased production times. Robots perform tasks like welding, painting, and assembly, ensuring high-quality output with minimal waste.

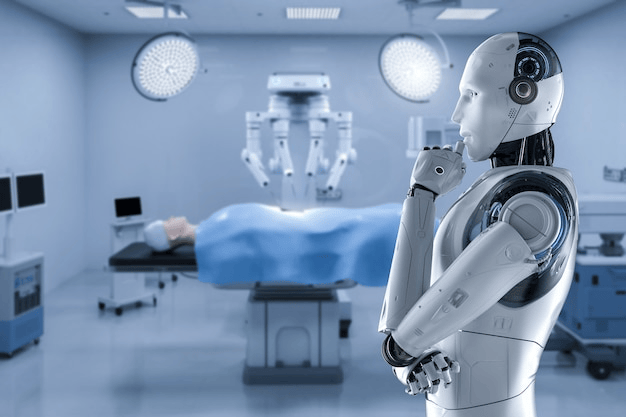

Robotics in Healthcare

The healthcare sector is embracing robotics to improve surgical precision, patient care, and even rehabilitation. From performing surgeries to assisting the elderly, robots are playing a significant role.

Surgical Robots

Surgical robots assist surgeons by providing enhanced precision during operations. They help reduce human error, lower the risk of complications, and ensure quicker recovery times for patients.

Rehabilitation Robots

Rehabilitation robots help patients recover lost functions after accidents or strokes. These robots aid in physical therapy, guiding patients through exercises and helping them regain mobility.

Robotics in Elderly Care

With an aging population worldwide, robots are being developed to assist the elderly with daily tasks. These robots help with mobility, medication management, and companionship, ensuring the elderly can live independently for longer.

Robotics in Agriculture

Agriculture is another sector that is benefiting greatly from robotics. Farmers are adopting robots to make farming more efficient, sustainable, and less reliant on human labor.

Precision Farming

Robots equipped with sensors and artificial intelligence (AI) are used for precision farming. They monitor soil conditions, check crop health, and even apply fertilizers and pesticides with pinpoint accuracy, reducing waste and environmental impact.

Harvesting Robots

Automated harvesting robots can pick fruits, vegetables, and other crops, reducing the need for seasonal labor. This technology ensures crops are harvested at the right time, leading to better yield and quality.

Drones in Agriculture

Drones are becoming essential tools for farmers. They are used to survey large fields, monitor crop health, and spray pesticides or fertilizers efficiently. Drones offer real-time insights into field conditions, helping farmers make informed decisions.

Robotics in Logistics and Supply Chain

Robots are revolutionizing logistics and supply chain operations by enhancing efficiency and reducing costs.

Autonomous Delivery Vehicles

Self-driving delivery vehicles are changing the way goods are transported. These vehicles can move packages from warehouses to customers, reducing delivery times and costs.

Robotics in Warehouses

In warehouses, robots are used for sorting, picking, packing, and even loading goods onto trucks. These robots increase efficiency by reducing human error and improving speed.

Drones for Inventory Management

Drones are now used for inventory management in large warehouses. They can quickly scan barcodes, take inventory, and provide real-time updates on stock levels.

Artificial Intelligence and Robotics: A Perfect Match

Artificial intelligence (AI) is revolutionizing robotics, making robots smarter and more capable of handling complex tasks.

AI Integration in Robotics

AI enables robots to make decisions based on data inputs and learn from experience. This allows robots to adapt to new environments, make predictions, and improve their performance over time.

Machine Learning and Robotics

Machine learning algorithms are enabling robots to perform tasks like pattern recognition and problem-solving. This makes robots more adaptable, allowing them to complete a wider variety of tasks.

The Impact of Robotics on the Workforce

As robotics becomes more prevalent, questions arise about how it will affect human workers. Will robots take over all jobs? Or will they complement human labor?

Job Creation vs. Job Displacement

While robots may replace some manual jobs, they are also creating new opportunities. The rise of automation has led to increased demand for skilled workers who can maintain, program, and operate robots.

Upskilling and Reskilling the Workforce

To stay competitive, workers must adapt by acquiring new skills. Upskilling programs focusing on robotics, AI, and automation are essential to ensure workers can thrive in the future job market.

Ethical Considerations in Robotics

As robots become more advanced, ethical questions surrounding privacy, safety, and decision-making arise. Society must find ways to address these concerns to ensure robots are used responsibly and ethically.

The Role of Robotics in Sustainability

Robots are not just making industries more efficient—they are also helping companies adopt more sustainable practices.

Green Robotics

Many robots are designed with energy efficiency in mind. By reducing the need for human intervention and optimizing energy usage, robots can significantly reduce the environmental impact of industrial processes.

Reducing Human Error and Waste

Robots’ ability to work with high precision means fewer mistakes are made, which reduces waste and increases the sustainability of manufacturing and agriculture.

Challenges and Barriers in the Robotics Industry

While robotics presents incredible opportunities, there are also several challenges that need to be addressed.

High Costs and Accessibility

The initial cost of implementing robotics technology can be expensive, making it difficult for smaller businesses to adopt. Over time, however, the cost of robotics is expected to decrease as technology advances.

Technical Challenges

Developing robots that can perform complex tasks with high precision remains a significant challenge for engineers. Innovations in AI, machine learning, and robotics design will be essential to overcome these hurdles.

Safety Concerns

Robots operating in environments with humans must be designed with safety in mind. Workplace accidents involving robots, though rare, highlight the need for better safety protocols and guidelines.

The Future of Robotics: What’s Next?

The future of robotics is full of promise. As technology continues to evolve, robots will become even more integrated into our daily lives and industries.

Advanced Robotics Trends

From advanced robots capable of complex surgeries to autonomous robots that can perform household chores, the future is filled with possibilities. Robotics will continue to evolve and bring new innovations to industries and homes alike.

The Rise of Autonomous Robots

The rise of autonomous robots will bring even more changes. These robots will be capable of performing tasks entirely on their own, making them valuable in industries such as healthcare, logistics, and agriculture.

Robotics and Human Augmentation

In the near future, robots may not just replace jobs but work alongside humans to enhance their abilities. Human augmentation through robotics could allow workers to achieve more than ever before.

Conclusion: Embracing the Future of Robotics

Robotics is no longer just a trend; it is transforming industries, improving efficiency, and creating new opportunities. As robots become more advanced and integrated into different sectors, the potential for innovation is limitless. By embracing this technology, businesses can improve productivity, reduce costs, and make industries more sustainable.

FAQs

1. What industries benefit the most from robotics?

Industries like manufacturing, healthcare, agriculture, and logistics have greatly benefited from robotics due to improved efficiency, precision, and automation.

2. Will robots replace human jobs?

While robots may replace some tasks, they also create new jobs in areas like robot programming, maintenance, and AI development.

3. How do robots contribute to sustainability?

Robots help reduce waste, improve energy efficiency, and minimize human error, making industries more sustainable.

4. What are collaborative robots (cobots)?

Cobots are robots designed to work alongside humans, performing repetitive or dangerous tasks, thus allowing workers to focus on more complex jobs.

5. How do robots use AI?

AI enables robots to make real-time decisions, adapt to new environments, and learn from experience, enhancing their capabilities and efficiency.

Please don’t forget to leave a review.